Welcome back ladies! Day 2 we will finish up our fun new Tillys and learn a little something new on how to make a flounce sleeve from any sleeve pattern! The possibilities just became endless. Now, if you are just joining me, click over to Day 1 to catch up and get in the know. :)

Yesterday we left off with the bodice almost finished save the buttons and sleeve hems. To begin Day 2, let's get to the hemming of the sleeves. Personally, I feel a flounce sleeve is best finished off with a bias tape hem. Now, don't go hating me and calling me bad words just yet, hear me out. I have 2 reasons I prefer this finish:

1. The beauty of the flounce sleeve is the way it is cut. Think about a circle skirt. The fabric just drapes beautifully because of the way it crosses the grain lines of the fabric with extra fullness at the base. The flounce sleeve is no different. The fabric becomes the magic here, and in my opinion, you have to add a little bit of weight to the bottom (ie. the hem) for that drape to happen properly, especially with a woven. Now, on a skirt it will drape anyways due to gravity, but a sleeve doesn't fall vertically, so we have to give it a little help. (That was your physics lesson for the day)

2. Second, again the shape of the flounce sleeve is swoon-worthy. But, it does have a downfall. Since it is a fuller sleeve (but only at the base) it will flounce around (giving its name justice) and you will see the inside of the sleeve. So, when you finish it off with bias tape, if you get a peek at the inside, it will be just as beautiful as the outside. You may think I am nuts considering I have exposed seams on the inside and here I am worrying about a sleeve hem, but trust me here.

All in all, the devil is in the details. ;)

So, now that you know the methods to my madness, let's get started. I have done a mini-tutorial on how to make your own bias tape. If you already now how, just skip on down. Or, if you buy pre-packaged (there is NO shame in this game, but I would go for the single fold) just keep scrolling until we attach it. If you are feeling rebellious and just want to hem your sleeve as normal, that is fine too. The sleeve I drafted has a 3/8" seam allowance included for the hem, not huge...but you can do it. We are still friends and you know I don't judge (said the girl with exposed seams). ;)

I pretty much always will pull bias tape off the scraps of whatever fabric I am going to use. It is no secret that cutting fabric on the bias can be a huge fabric-sucker, but it is so important to give it the ability to curve and lay how it should. I won't go too much into detail here, but when you cut fabric on the bias, you will realize that the fabric has a lot more give than it does on the grain. It also won't fray. Neat little tidbit here on a Wednesday morning. So, you want to start by establishing a 45 degree angle to your fabric grain lines as shown below. If you have a cutting board with your bias lines on it (as I do below), use them to your benefit. Line up the grain of your fabric with the lines on your board, and follow the 45 degree bias line as represented by the black line below. Once you have that angle, make a slice across the fabric. If you can see here, I am cutting 4 pieces of scrap (from where I cut the bodice) at the same time to maximize the amount of strips I have with minimal cuts.

Once your angled cut is made, flip your fabric around (I do this to make the cuts easier for me being right-handed) and cut strips that are 1.5" wide. Cut as many as you can out of your scraps.

Once you have your scraps, it is time to join them together. You will line 2 scraps up, right sides together as shown below. To attach them, you will sew them together at a 45 degree angle as shown by the black line below. Do this until you have one long piece of bias tape (I usually do about 6-8 strips, enough to cover the circumference of both sleeve hems, real rocket science here as you can tell).

Once all the strips are sewn together, clip the seam allowances as shown below. The black dotted line is my seam line.

Now, take to the iron and press all of the seams out.

Once the seams are pressed, go along the strips and cut off all the excess points as shown below.

Last step. Grab your handy bias strip maker (if you have one, if not I highly recommend you ask Santa for a few, I use mine often) and press the raw edges into the center as shown below. You will leave it as a single fold, instead of folding the bias in on itself again. And see, bias is done. If you had good tunes I bet that went quicker than you planned. If that was your first time, add another skill to your set!

Now to put that bias to work. I usually will just make sure that I have enough bias tape to hem both sleeves before I get started. No one has time to start only to realize they need more bias tape. Once you have made sure you have plenty, head over to your machine with your bias tape and your bodice. We are going to be sewing the bias to the RIGHT side of the sleeve. Find your sleeve seam, and put the edge of your bias tape along it, making sure to open one fold of the bias so that the raw edge lines up with the raw edge of your sleeve, right sides together. Now, you will not start stitching the tape to the sleeve at the sleeve seam, instead, bump it down about 1" or so and start sewing there. The photo below shows this with the purple x.

As you stitch, stay within the fold of your bias tape. Since your tape was a 1.5" strip, this should be lining up perfectly with a 3/8" seam allowance.

Keep stitching all the way around the bottom of the sleeve, but slow down as you come back around to the sleeve seam. Below, again the purple x is where I started my stitch.

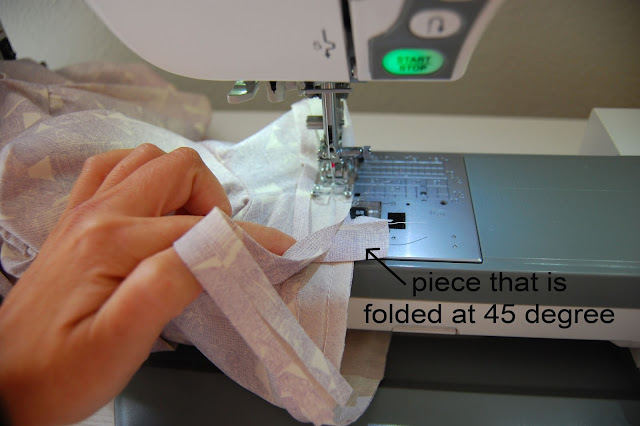

I usually leave my needle down right as I pass over the sleeve seam. Grab the edge of your bias tape that you started with, and fold it down at a 45 degree angle as shown below. This is why we left that 1" gap with no stitching when we started.

Once folded over, place the other end of bias (the one you are currently stitching down) over the edge you just folded at an angle, making sure to keep the raw edges in line with the sleeve.

You will continue stitching just as you have been, OVER the edge you folded and about an inch more, as shown below with the black arrow. The yellow dashed line represents the edge you folded.

Once stitched, cut the excess of your bias tape as shown below with the black line.

Now, take over to the ironing board and press the bias tape over the seam allowance and press towards the bottom of the sleeve as shown by the arrow below.

This is what it should look like where you folded the starting edge at an angle. See how it gives you a nice finished edge?

Now, flip the sleeve inside out and press the bias tape to the inside of the sleeve along the line you just stitched.

This picture shows once it has been folded in and how you can just barely see the seam line.

As you press all along the hem, you will come to the point where your edge was folded. Again, this makes for a nice, finished and pretty hem.

Once pressed, take to the machine and stitch the hem. I love this finish as well because it gives the appearance of a nice, wide hem on the outside, yet the inside is just as beautiful!

Repeat with the other strip of bias and sleeve and then get ready to call it a day with the bodice! I am a creature of habit and like to have the bodice finished before I go to the skirt, so I go ahead and stitch my buttons on at this point as well. I didn't take photos of this, because I figured if you are used to BG patterns, buttons are a common task that you can probably all do in your sleep by now!

Now to the skirt!! We made changes to the bodice as far as dropping the bodice and shaping it, so our skirt needs to reflect that. I hope you remembered the numbers from yesterday that we added to the bodice, as they are important now. I am just glad mine are in writing as I have already forgotten them. Ha! Now, this next step may be overkill, especially since BG designs are made in vintage lengths (read as short dresses) but as you know, I always sometimes every now and then am crazy about like details. So, since I added length to the bodice, I need to take that amount away from my skirt piece. However, the only number I am going to be concerned with right now is the amount I added to the center, which in my case was 1.25". So, I am going to take that amount away from the skirt piece I cut. So, since I am making a 4-5 top here, the cutting chart on page 8 of the pattern tutorial says I should cut 2 pieces that are 11.25" in length. But I won't. Instead, I will cut 2 pieces that are 10" in length. Since you know I love equations, here we go:

Skirt length according to size on page 8 - Amount added to center of bodice = New length to cut skirt pieces

In my case: 11.25 - 1.25 = 10

Okay, hopefully we are all on the same page. Math homework at my house lately (I love math like another child but my Lou doesn't share the same emotions for it, sigh) has been so rough, I am afraid one day in my patterns I will follow up to what Lou accuses me of..."Ugh you're making this so much harder than it should be!" Don't get me started on 9 year old hormones/attitudes this morning.

Once your skirt pieces are cut, lay them out flat, but on the fold. We have one more modification to make to them. Now, to use the other measurement from our bodice, the one we added to the exterior. Mine was 2.5", so I am going to measure down 2.5" on the cut sides of my skirt piece (NOT THE FOLD SIDE) and make a mark. I have both of my skirt pieces stacked here on the fold to make the process quicker.

Now, you are going to draw a line that is similar to the curve of your bodice from the fold of your skirt pieces to the mark you just made from the exterior bodice drop. Dropbox has eaten the photo I did of that step, so instead below I have shown you what mine looks like once it is cut, and the yellow dashed line represents where the straight lines of the skirt pieces used to be. This doesn't have to be perfect, but you do need to mirror the curve shape the best you can.

Once you are happy with the curve, put skirt pieces right sides together and sew along the edges as shown by the black lines below. Finish those seams and then sew 2 gathering stitches along the top, curved part of the skirt piece. You will sew the gathering stitches for the front and back skirt pieces separately to make it easier to gather in the round in just a bit.

Now, place your skirt wrong sides out on a flat surface, and slide your bodice, right sides out up into the skirt as shown below. You will then match up and pin together the skirt side seams with the bodice and the front center of the bodice with the front center or the skirt and then the back center of the bodice with the back center of the skirt.

Once you have it all pinned in those 4 spots, pull the skirt fabric along the gathering stitches to fit the bodice and pin in place as you go. Below is what it will look like when finished. Stitch the skirt to the bodice and then finish that seam.

Press the skirt seam up towards the bodice and top-stitch now if you please. Hem the bottom of your skirt according to the instructions in the pattern tutorial and guess what???

YOU ARE DONE! Congrats to you for an awesome Tilly hack. I cannot wait to see what everyone creates, so make sure to share your Tilly Flounces in the brownie-goose lovers group on Facebook!

And now for a mini-tutorial that just might make you dangerous in the sewing room. ;) I am going to walk you though the steps that you will need to turn any sleeve into a flounce.

Start off with whatever sleeve you choose and have it cut out on tracing paper, or regular paper, pick your poison. Y'all know how I love my tracing paper. I am showing this tutorial on a sleeve drafted on the fold. This certainly works on sleeves not on the fold as well.

First step, measure 1/2" off the fold and make a mark parallel with the fold. (Now, if you have a sleeve not on the fold, make the marks off the center of the sleeve cap.) Once that line is drawn, measure over 1" now and make a line parallel to the fold. Continue along this path until you have run out of space on your sleeve.

Now, with scissors you are going to cut along those lines. Start at the bottom of your sleeve and cut up to BUT NOT THROUGH the sleeve cap. I usually will leave a space of 1/8" between the sleeve cap and my cut. This is the slashing part.

See how I have cut along the lines, but the sleeve is still together at the cap? This is the beauty of it. It keeps the sleeve cap the same but allows us to change the shape of the sleeve. I love things like this.

Now, grab another piece of paper or tracing paper, and tape your cut sleeve down to the paper at the top and bottom of the fold line as shown by the arrows below.

Time for the spreading part. Since the fold of your sleeve is taped in place, position the next piece so that there is a 1" gap between the pieces at the bottom as shown below. Once you have it positioned just right, tape it in place.

Continue along this method, making the 1" spaces and taping the sleeve in place. Depending on the height of your sleeve cap, you may have to do some maneuvering to keep it laying flat, but do not let that stress you. Now, if you want more of a flounce, make your spaces more than 1" and less of a flounce would be less than 1". For me, I found 1" was the magic number with the Tilly although feel free to play around with it all!

Once you have all of your pieces spaced and taped, trace along the outer edges of your new sleeve.

Cut along those lines and see how you have a brand new flounce sleeve!!

Say you want to shorten that sleeve. All you would do is decide how much you wanted off the hem and measure up that amount (below I showed 2") all along the bottom of the sleeve and then cut along the line.

Now ladies you are armed and dangerous in the sewing room. Go get crazy with some hacks and flounces! Let your creativity flow!!

Thanks again for following along and being patient in the process! The holiday season is about to get started and so I hope each and everyone of you has one full of good memories, happiness, fun and family!

Xoxo - Amy